Nuclear

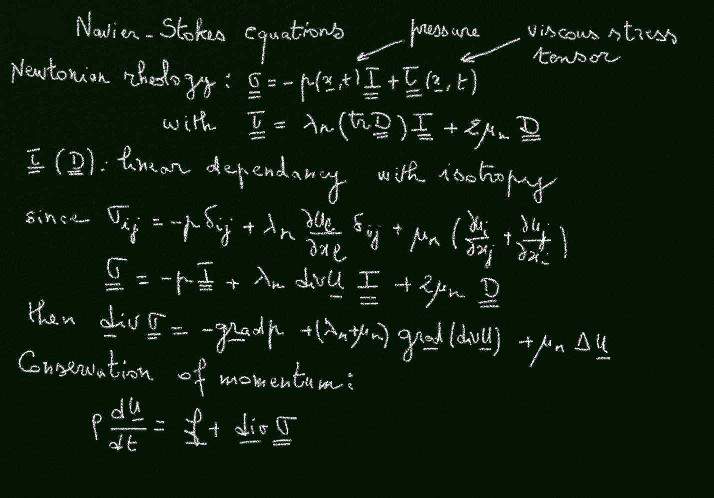

Cooling Drowned Pump Motor

Context

The objective was to validate the insulation class of the materials used in a pump used in nuclear-type reactors.

Resolution

This project consisted of a thermo-hydraulic analysis to quantify coolant flow rates and associated heat exchanges.

Results

The results obtained made it possible to quantify heat transfers and highlight the hottest areas. The numerical experiment approach has also made it possible to guarantee the insulation class of the products.

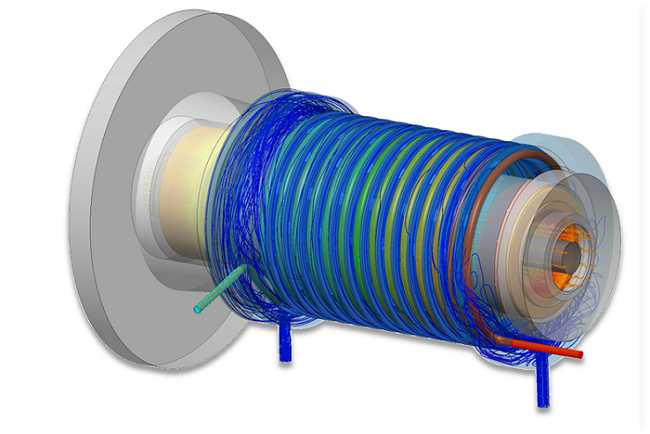

Emergency Diesels Room

Context

The purpose of this project was to determine the intake temperatures of emergency diesel engines in the event of a “Big Hot” plan. The final goal was to verify the absence of overheating and associated malfunctions.

Resolution

The project started with the 3D modeling of the ventilation network, the engine room and the 3 diesel engines. The second step was the integration of heat sources in the room. Finally, the third and last part consisted of a calculation of the temperature and intake speed of the engines.

Results

The results were used to map velocities and temperatures in the rooms, and to validate their design in the face of heat wave events.

The study also enabled the client to validate its 1D code and meet the expectations of the DHA.

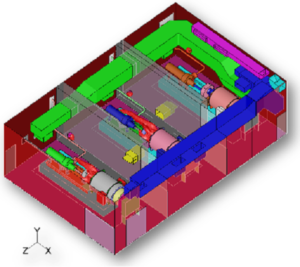

Accidental Rupture and Flash Vaporization

Context

The objective of this project was to characterize the flow through a check valve in the event of an accidental open rupture of a downstream piping system.

Resolution

4 configurations have been studied: two stem positions and two fluid temperatures for each position. Subsequently, two-phase analyses, including turbulence and cavitation phenomena, were carried out.

Results

The results were used to determine the mass flow through the valve, the forces exerted by the flows on the stem and the detection of potential vortex under the stem. Thanks to numerical simulation, we were able to locate the regions where the vapors appear and the percentage of vapor in the flow downstream of the valve.